Industrial environments are often synonymous with high noise levels. Heavy machinery, ventilation systems, generators, compressors, and production lines all contribute to excessive sound that can affect worker health, productivity, and regulatory compliance. Industrial soundproofing is not just about comfort. It is a critical operational requirement for safety, efficiency, and long-term sustainability.

This step-by-step guide to implementing industrial soundproofing explains the complete process, from noise assessment to material selection and installation. Whether you manage a factory, warehouse, power plant, or manufacturing unit, this guide will help you make informed decisions that lead to measurable noise reduction and compliance with occupational standards.

Understanding Industrial Soundproofing and Its Importance

Industrial soundproofing refers to a combination of acoustic treatments, structural modifications, and specialized materials used to reduce noise transmission within and outside industrial spaces. Unlike basic sound treatment, industrial soundproofing focuses on controlling high-decibel noise, low-frequency vibrations, and continuous operational sounds.

Excessive industrial noise can lead to hearing loss, fatigue, reduced productivity, communication issues, and legal penalties due to non-compliance with workplace noise regulations. Implementing soundproofing solutions protects workers, improves operational efficiency, and enhances the overall work environment.

Step 1: Conduct a Comprehensive Noise Assessment

Identify Noise Sources in Industrial Facilities

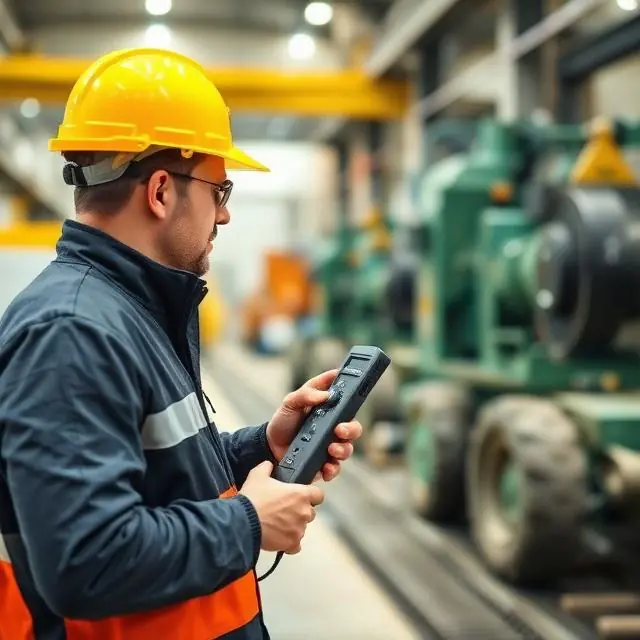

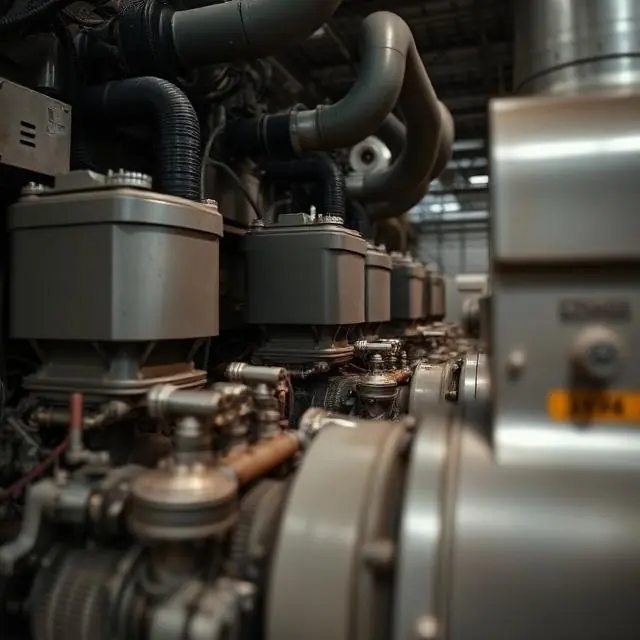

The first step in any industrial soundproofing project is understanding where the noise originates. Common industrial noise sources include heavy machinery, HVAC systems, generators, turbines, conveyors, and impact-based operations.

A professional noise assessment identifies both airborne noise and structure-borne vibrations. This step ensures that soundproofing solutions target the root cause rather than just masking the noise.

Measure Decibel Levels and Frequency Ranges

Different soundproofing materials perform better at specific frequencies. Industrial noise often includes low-frequency sounds that require dense and layered materials.

Noise measurements should include:

- Average and peak decibel levels

- Frequency spectrum analysis

- Noise exposure duration

- Areas affected by noise transmission

Accurate data helps in selecting the right soundproofing strategy and materials.

Step 2: Define Soundproofing Goals and Compliance Requirements

Set Noise Reduction Targets

Before implementation, define clear objectives. These may include reducing noise to permissible exposure limits, minimizing sound leakage to adjacent areas, or improving acoustic comfort for operators.

Soundproofing goals should be measurable and aligned with workplace safety standards.

Understand Local and International Noise Regulations

Industrial soundproofing must comply with occupational health and safety guidelines. Regulations often specify maximum allowable noise exposure levels for workers over specific durations.

Meeting these standards reduces legal risks and demonstrates commitment to employee well-being.

Step 3: Choose the Right Industrial Soundproofing Strategy

Sound Absorption vs Sound Blocking

Industrial soundproofing typically involves a combination of absorption and blocking techniques.

Sound absorption reduces echo and reverberation within a space using acoustic panels, foam, or mineral wool. Sound blocking prevents noise from escaping or entering an area using dense barriers and enclosures.

An effective strategy balances both approaches based on noise type and space layout.

Structural and Non-Structural Solutions

Structural soundproofing includes modifying walls, ceilings, floors, and partitions. Non-structural solutions include acoustic enclosures, barriers, and machinery isolation systems.

The choice depends on operational needs, budget, and whether permanent modifications are feasible.

Step 4: Select Appropriate Industrial Soundproofing Materials

Common Soundproofing Materials Used in Industrial Settings

Choosing the right materials is crucial for performance and durability. Industrial environments demand materials that withstand heat, moisture, vibration, and heavy usage.

Commonly used materials include:

- Acoustic panels and boards

- Mineral wool and rock wool insulation

- Mass loaded vinyl barriers

- Perforated metal panels with acoustic backing

- Acoustic foam for high-frequency absorption

- Vibration isolation mounts and pads

Each material serves a specific purpose and works best when combined strategically.

Fire Safety and Durability Considerations

Industrial soundproofing materials must comply with fire safety standards and be resistant to chemicals, humidity, and mechanical wear. Long-term durability ensures consistent performance and reduces maintenance costs.

Step 5: Design Customized Soundproofing Solutions

Acoustic Design and Space Planning

Every industrial facility has unique acoustic challenges. Custom acoustic design ensures soundproofing solutions integrate seamlessly with operations.

Key design considerations include:

- Machinery placement and enclosure design

- Wall and ceiling surface treatments

- Door and window sealing

- Ventilation without sound leakage

- Accessibility for maintenance

A tailored design maximizes noise reduction without disrupting workflow.

Addressing Vibration and Structure-Borne Noise

Machinery vibrations can transmit sound through floors and walls. Vibration isolation systems such as anti-vibration pads, floating floors, and resilient mounts play a vital role in industrial soundproofing.

Ignoring vibration control can significantly reduce the effectiveness of soundproofing efforts.

Step 6: Professional Installation and Execution

Importance of Correct Installation

Even the best soundproofing materials fail if installed incorrectly. Gaps, weak joints, and improper sealing allow sound to leak through.

Professional installation ensures:

- Airtight sealing of panels and enclosures

- Correct layering of materials

- Secure mounting to prevent rattling

- Integration with ventilation and electrical systems

Precision during installation directly impacts noise reduction performance.

Minimizing Operational Downtime

Industrial soundproofing projects should be planned to minimize disruption. Phased installation, off-hour work schedules, and modular systems help maintain productivity during implementation.

Step 7: Testing, Validation, and Optimization

Post-Installation Noise Testing

After installation, conduct noise measurements to verify results. Compare post-installation data with initial assessments to confirm that soundproofing goals have been met.

Testing validates performance and identifies any remaining problem areas.

Continuous Improvement and Maintenance

Industrial environments change over time. New machinery, increased production, or layout changes can affect noise levels.

Regular inspections and maintenance ensure that soundproofing systems remain effective and compliant.

Benefits of Implementing Industrial Soundproofing

Effective industrial soundproofing delivers long-term value beyond noise reduction.

Key benefits include:

- Improved worker health and safety

- Enhanced productivity and focus

- Compliance with noise regulations

- Reduced equipment wear caused by vibration

- Better communication and morale

- Positive brand image and workplace reputation

Soundproofing is an investment that pays off through operational efficiency and employee retention.

Why Choose SoundKrafted.com for Industrial Soundproofing Solutions

When it comes to implementing industrial soundproofing, expertise and material quality matter. At SoundKrafted.com, we provide professional soundproofing services and high-performance acoustic materials tailored for industrial environments.

Trusted Expertise in Industrial Acoustic Solutions

SoundKrafted.com specializes in soundproofing solutions for factories, warehouses, manufacturing plants, studios, commercial spaces, and specialized industrial facilities. Our team understands complex noise challenges and delivers customized solutions backed by technical expertise.

End-to-End Soundproofing Services

We offer complete support throughout the soundproofing journey, including:

- Noise assessment and acoustic consultation

- Custom design and material selection

- Supply of certified soundproofing materials

- Professional installation and project execution

- Post-installation testing and optimization

This end-to-end approach ensures reliable and measurable noise reduction.

High-Quality Materials for Industrial Performance

SoundKrafted.com provides soundproofing materials designed for durability, fire safety, and industrial-grade performance. Our solutions are engineered to handle demanding environments while delivering consistent acoustic results.

Proven Trust and Client Satisfaction

Clients trust SoundKrafted.com for our transparent processes, technical accuracy, and commitment to long-term results. Our focus on compliance, safety, and performance makes us a reliable partner for industrial soundproofing projects of all sizes.

Conclusion: Take Control of Industrial Noise with the Right Soundproofing Strategy

Implementing industrial soundproofing is a structured process that requires careful planning, expert design, and professional execution. From assessing noise sources and setting clear goals to selecting materials and ensuring correct installation, every step plays a crucial role in achieving effective noise control.

Industrial soundproofing improves worker safety, boosts productivity, and ensures compliance with regulatory standards. With the right approach and trusted professionals, noise challenges can be transformed into manageable and sustainable solutions.

If you are ready to reduce industrial noise and create a safer, more efficient workspace, SoundKrafted.com offers reliable soundproofing services and materials designed to meet your specific needs. Contact us today to begin your journey toward effective industrial soundproofing and long-term acoustic comfort.