Industrial noise is more than an inconvenience. It directly affects worker safety, productivity, regulatory compliance, and even brand reputation. Manufacturing plants, warehouses, power plants, and processing units often struggle with excessive noise from machinery, HVAC systems, compressors, and material handling operations.

The good news is that effective industrial soundproofing does not always require expensive overhauls or complex structural redesigns. With the right strategies, materials, and planning, businesses can implement cost-effective industrial soundproofing techniques that significantly reduce noise without exceeding budgets.

This comprehensive guide explores practical, affordable, and proven soundproofing methods for industrial environments. It also explains how to choose the right approach based on your facility’s needs and why trusted experts like soundkrafted.com play a critical role in long-term success.

Understanding Industrial Noise and Its Impact

Before selecting soundproofing solutions, it is important to understand why industrial noise control matters.

Excessive noise can lead to:

- Hearing loss and long-term health issues for workers

- Reduced concentration and productivity

- Higher employee turnover and absenteeism

- OSHA and local regulatory violations

- Complaints from nearby residential or commercial areas

Industrial soundproofing is not just about comfort. It is about compliance, safety, and operational efficiency.

Key Principles of Cost-Effective Industrial Soundproofing

Effective noise control does not rely on a single solution. It involves combining multiple strategies that target how sound is generated, transmitted, and absorbed.

The three core principles are:

- Sound absorption to reduce echo and reverberation

- Sound blocking to prevent noise transmission

- Sound isolation to separate noise sources from occupied spaces

Cost-effective industrial soundproofing focuses on optimizing these principles without unnecessary structural changes.

Sound Absorbing Materials for Industrial Spaces

Using Acoustic Panels and Industrial Absorbers

Acoustic panels are one of the most affordable and effective soundproofing solutions for industrial environments. These panels absorb sound waves and reduce reverberation within large spaces.

Industrial-grade acoustic panels are designed to withstand harsh conditions such as dust, humidity, and temperature fluctuations.

Benefits include:

- Improved speech clarity and communication

- Reduced background noise levels

- Easy installation on walls and ceilings

- Minimal disruption to operations

Panels made from mineral wool, fiberglass, or recycled materials provide excellent absorption at a reasonable cost.

Acoustic Ceiling Treatments

High ceilings amplify noise in factories and warehouses. Installing acoustic ceiling baffles or clouds helps trap sound before it spreads.

Ceiling treatments are cost-effective because:

- They utilize unused vertical space

- They do not interfere with machinery layouts

- They significantly reduce overall noise levels

This approach is especially useful in metal fabrication plants and assembly lines.

Machinery Enclosures and Barriers

Partial and Full Machine Enclosures

One of the most direct cost-effective industrial soundproofing techniques is enclosing noisy machinery. Instead of soundproofing the entire facility, targeting the noise source yields faster results.

Machine enclosures can be:

- Partial enclosures for access and ventilation

- Full enclosures for high-noise equipment

These enclosures use soundproof panels combined with absorptive linings to reduce noise at the source.

Advantages include:

- Lower material costs compared to building-wide solutions

- Improved compliance with noise regulations

- Enhanced worker safety

Portable Noise Barriers

Portable sound barriers are flexible solutions for changing industrial environments. They are ideal for temporary setups or areas with fluctuating noise sources.

Key benefits:

- Low upfront cost

- Easy relocation and reconfiguration

- Quick installation without construction

Portable barriers are often used around welding stations, generators, or testing areas.

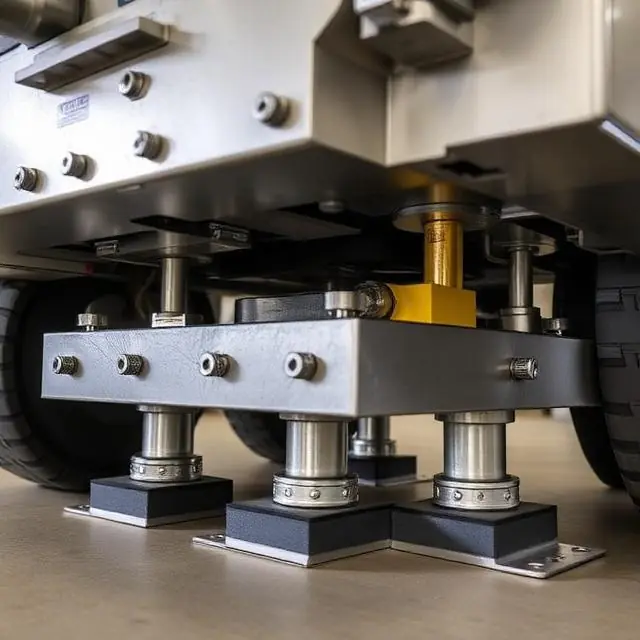

Vibration Isolation for Noise Reduction

Controlling Structure-Borne Noise

Not all industrial noise travels through air. A significant portion is transmitted through vibrations in floors, walls, and structural elements.

Cost-effective vibration isolation methods include:

- Anti-vibration pads under machinery

- Isolation mounts for motors and compressors

- Resilient floor underlays

These solutions reduce noise at its source and prevent it from spreading throughout the facility.

Equipment Maintenance as a Soundproofing Strategy

Regular maintenance is an often overlooked noise control technique. Poorly maintained equipment produces more noise due to friction, imbalance, and wear.

Simple steps include:

- Lubricating moving parts

- Replacing worn bearings

- Tightening loose components

Preventive maintenance reduces noise without additional soundproofing investments.

Sealing Gaps and Weak Points

Doors, Windows, and Openings

Sound easily escapes through gaps, cracks, and poorly sealed openings. Addressing these weak points is one of the most cost-effective industrial soundproofing techniques.

Solutions include:

- Acoustic door seals and gaskets

- Soundproof curtains for large openings

- Double-glazed or laminated industrial windows

Sealing gaps improves noise control while also enhancing energy efficiency.

Duct and Vent Noise Control

Ventilation systems often act as noise pathways. Instead of blocking airflow, use acoustic duct liners or silencers.

These treatments:

- Reduce noise transmission through HVAC systems

- Maintain airflow and cooling efficiency

- Are relatively low-cost compared to redesigning ductwork

Optimizing Layout and Space Planning

Strategic Equipment Placement

Reorganizing machinery layouts can significantly reduce noise exposure without spending on materials.

Best practices include:

- Placing noisy equipment away from workstations

- Grouping high-noise machines in isolated zones

- Using storage areas as buffer zones

This approach costs little but delivers noticeable improvements.

Creating Quiet Zones

Designating low-noise areas for administrative tasks or quality control helps protect workers without extensive soundproofing.

Simple solutions include:

- Acoustic partitions

- Soundproof booths

- Enclosed offices within production floors

Cost-Benefit Analysis of Industrial Soundproofing

Investing in soundproofing delivers long-term financial benefits.

Key returns include:

- Reduced workers compensation claims

- Improved employee retention

- Lower risk of regulatory fines

- Enhanced operational efficiency

Cost-effective solutions focus on achieving acceptable noise levels rather than complete silence.

Common Mistakes to Avoid in Industrial Soundproofing

Even budget-friendly projects can fail if not planned properly.

Avoid these mistakes:

- Relying on a single solution for all noise problems

- Ignoring low-frequency noise issues

- Choosing residential-grade materials for industrial use

- Overlooking ventilation and safety requirements

Professional assessment ensures the right balance between cost and performance.

Why Choose soundkrafted.com for Industrial Soundproofing Solutions

When it comes to reliable and cost-effective industrial soundproofing, businesses trust soundkrafted.com for proven expertise and tailored solutions.

At soundkrafted.com, we provide professional soundproofing services and high-quality acoustic materials for a wide range of industrial spaces, including factories, warehouses, power plants, and commercial facilities.

What Sets soundkrafted.com Apart

- Industry-specific soundproofing solutions designed for real-world conditions

- High-performance acoustic materials tested for durability and efficiency

- Customized designs based on noise assessments and budget constraints

- End-to-end services from consultation to installation

- Compliance-focused solutions aligned with safety and regulatory standards

Our team understands that every industrial environment is unique. We focus on delivering measurable noise reduction without unnecessary costs or downtime.

Businesses choose soundkrafted.com because we combine technical expertise with practical implementation, ensuring long-term value and performance.

Future Trends in Cost-Effective Industrial Soundproofing

Advancements in materials and design continue to make soundproofing more affordable.

Emerging trends include:

- Sustainable acoustic materials made from recycled fibers

- Modular soundproofing systems for easy expansion

- Smart noise monitoring to optimize solutions over time

Staying updated with these trends helps industries reduce costs while improving outcomes.

Conclusion and Call to Action

Cost-effective industrial soundproofing is achievable with the right combination of materials, strategies, and professional guidance. By focusing on sound absorption, vibration control, machinery enclosures, and smart space planning, industries can significantly reduce noise without overspending.