In today’s rapidly evolving industrial landscape, control and automation systems have become indispensable for managing complex operations efficiently. However, one critical aspect often overlooked is the acoustic environment where these control and automation systems operate. Whether you’re managing a manufacturing plant, broadcasting studio, or command center, the integration of proper soundproofing solutions with your control and automation systems can dramatically enhance operational efficiency and worker safety.

Understanding Modern Control & Automation Systems

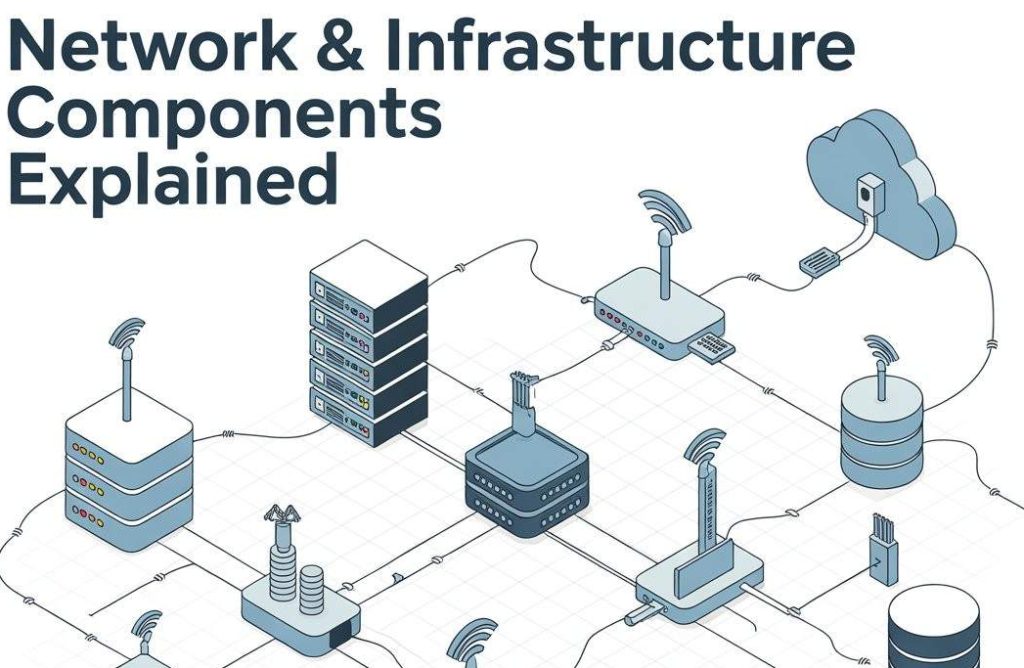

Control and automation systems represent the technological backbone of contemporary industrial operations. These sophisticated networks integrate sensors, actuators, processors, and communication protocols to monitor and manage equipment automatically. From production lines to HVAC systems, control and automation systems enable precise management of industrial processes while reducing human intervention and minimizing errors.

The effectiveness of automation systems largely depends on the environment they operate within. Excessive noise, vibrations, and acoustic interference can compromise both equipment performance and operator decision-making. Therefore, implementing comprehensive acoustic treatment alongside your control and automation systems is not just beneficial—it’s essential for optimal functionality.

The Critical Connection Between Acoustics and Automation

Why Soundproofing Matters for Control Rooms

Modern control rooms house sensitive control and automation systems that monitor critical operations. These spaces require exceptional acoustic design to ensure clear communication, accurate audio monitoring, and minimal distractions. Studies show that operators in properly soundproofed control rooms make 35% fewer errors compared to those in acoustically untreated environments.

When control and automation systems are installed in noisy industrial settings without proper acoustic treatment, several problems arise. Operators struggle to hear alarms and communications clearly. Equipment monitoring becomes unreliable. Moreover, prolonged exposure to industrial noise levels above 85 decibels can cause permanent hearing damage, creating both safety and legal concerns.

Industrial Noise Sources That Affect Automation

Industrial facilities containing automation systems face multiple noise challenges. Machinery vibrations transmit through floors and walls. HVAC systems create constant background hum. Cooling equipment for servers generates additional noise. Automated equipment produces intermittent but disruptive sounds. All these factors combine to create an acoustic environment that undermines the effectiveness of even the most advanced automation systems.

Essential Acoustic Solutions for Automated Environments

1. Soundproof Control Room Design

Creating acoustically isolated control rooms is paramount for protecting operators managing automation systems. These dedicated spaces should incorporate multiple layers of soundproofing, including mass-loaded vinyl barriers, acoustic doors rated for 40+ STC (Sound Transmission Class), and specialized windows with laminated glass construction.

The walls should feature decoupled construction to prevent vibration transmission. Ceilings require suspended acoustic panels to absorb reverberations. Furthermore, all penetrations for cables, conduits, and HVAC must be sealed with acoustic caulking to maintain the sound isolation integrity.

2. Equipment Enclosures for Automated Machinery

Automated equipment controlled by your automation systems generates significant noise during operation. Consequently, custom-designed acoustic enclosures provide effective source control. These modular systems feature steel frameworks with removable panels, allowing maintenance access while dramatically reducing noise emissions by 20-35 decibels.

For equipment requiring ventilation, acoustic louvres enable airflow while maintaining sound attenuation. Additionally, vision panels allow operators to monitor machinery without compromising the acoustic barrier. This approach ensures your control and automation systems can function optimally without disturbing adjacent work areas.

3. Acoustic Treatment for Server Rooms

Server infrastructure supporting control and automation systems requires careful acoustic management. These rooms typically contain numerous heat-generating components with associated cooling equipment creating substantial noise. Moreover, the constant fan noise can exceed 75 decibels, creating an uncomfortable and potentially hazardous environment.

Implementing absorptive wall panels reduces reverberation within server rooms. Installing acoustic ceiling tiles further improves sound absorption. Furthermore, isolating server racks on vibration-dampening platforms prevents structure-borne noise transmission. These measures create a quieter environment for IT staff while protecting sensitive control and automation systems from acoustic interference.

4. Industrial Acoustic Barriers and Screens

Large manufacturing facilities utilizing automation systems benefit significantly from strategically placed acoustic barriers. These freestanding screens effectively partition noisy production areas from quieter administrative or control zones. Unlike permanent walls, acoustic barriers offer flexibility for reconfiguration as operational needs change.

Modern acoustic barriers feature dual-sided absorption, typically achieving 10-15 decibel reductions. They are designed to work well in an industrial setting with sturdy steel or aluminum material. Additionally, their modular design allows rapid installation without disrupting ongoing operations controlled by your automation systems.

5. Vibration Isolation for Automated Equipment

Vibration represents a significant challenge for automation systems. Structure-borne vibrations travel through building frameworks, creating noise in distant areas and potentially affecting sensitive monitoring equipment. Therefore, implementing comprehensive vibration isolation becomes crucial.

Spring-mounted platforms decouple heavy machinery from floor slabs. Elastomeric pads under equipment reduce vibration transmission. Moreover, flexible connections on pipes and ducts prevent vibration transfer through utility systems. These isolation techniques protect both your control and automation systems and the broader facility from disruptive vibrations.

6. Acoustic Doors and Windows for Control Zones

Standard doors and windows represent weak points in otherwise soundproof environments housing control and automation systems. Consequently, specialized acoustic doors featuring solid cores, perimeter seals, and automatic drop seals become essential. These doors achieve STC ratings of 40-50, maintaining acoustic integrity when closed.

Similarly, acoustic windows employ laminated glass with different thickness layers to disrupt sound transmission. Strategic placement allows operators to observe processes controlled by automation systems while maintaining quiet conditions within control rooms. Additionally, double-glazing with air gaps provides superior sound isolation compared to single-pane alternatives.

7. Comprehensive Acoustic Planning Integration

Effective acoustic treatment for facilities with control and automation systems requires holistic planning from the design phase. This integrated approach considers equipment placement, workflow patterns, communication needs, and future expansion possibilities. Moreover, acoustic modeling software helps predict sound transmission patterns before construction begins.

Professional acoustic consultants analyze your specific control and automation systems requirements, measuring existing noise levels and identifying problem sources. They then design customized solutions incorporating the appropriate combination of absorption, isolation, and barrier techniques. This comprehensive planning ensures maximum effectiveness while optimizing your investment.

Implementation Strategies for Maximum Effectiveness

Assessing Your Current Acoustic Environment

Before implementing acoustic solutions around your control and automation systems, conduct a thorough assessment. Professional sound level measurements identify specific problem frequencies and sources. Furthermore, recording operator feedback reveals practical concerns that measurements might overlook.

This baseline data guides solution selection and establishes benchmarks for measuring improvement after installation. Additionally, understanding your facility’s unique acoustic challenges ensures you invest in appropriate solutions rather than generic approaches that may prove inadequate for your control and automation systems.

Prioritizing High-Impact Areas

Budget constraints often necessitate phased implementation of acoustic improvements. Therefore, prioritize areas where control and automation systems operators spend the most time or where acoustic problems are most severe. Control rooms typically offer the highest return on investment, followed by equipment enclosures for the noisiest machinery.

Subsequently, expand acoustic treatment to communication zones, break areas, and circulation paths. This strategic approach delivers immediate improvements in critical areas while establishing a roadmap for comprehensive facility-wide acoustic optimization around your control and automation systems.

Maintenance and Long-term Performance

Acoustic treatments require ongoing maintenance to preserve their effectiveness. Regularly inspect acoustic seals on doors and windows, replacing deteriorated gaskets promptly. Furthermore, check acoustic panels for damage or contamination that might reduce absorption performance.

Moreover, as you upgrade or reconfigure automation systems, reassess acoustic requirements. New equipment may introduce different noise profiles requiring adjusted acoustic treatments. Periodic sound level measurements verify that your acoustic solutions continue meeting established standards.

Soundkrafted: Your Partner in Acoustic Excellence

At Soundkrafted, we specialize in creating optimal acoustic environments for facilities utilizing advanced control and automation systems. Our team understands the unique challenges industrial settings present and designs comprehensive solutions tailored to your specific requirements.

Services include full turn-key solutions ranging from initial acoustics analysis, design, material delivery, expert installation, and finally acoustics verification post-installation.. Our solutions incorporate premium acoustic materials including specialized panels, mass-loaded vinyl barriers, acoustic doors, and custom enclosures engineered for durability in demanding industrial environments.

Whether you’re constructing a new facility or retrofitting existing spaces housing control and automation systems, Soundkrafted delivers results that enhance operational efficiency, ensure regulatory compliance, and protect worker health. Our projects span manufacturing plants, broadcasting studios, data centers, and command facilities throughout Pakistan and the UAE.

Conclusion

The integration of proper acoustic treatment with automation systems represents a critical investment in operational excellence and worker wellbeing. As industrial facilities become increasingly automated and complex, creating acoustically optimized environments becomes more important than ever. By implementing comprehensive soundproofing solutions—from control room isolation to equipment enclosures—you enable your automation systems to function at peak efficiency while protecting your most valuable asset: your people.

Don’t let inadequate acoustics undermine your sophisticated automation infrastructure. Partner with acoustic professionals who understand both the technical requirements of control and automation systems and the practical realities of industrial operations. The result will be a facility that operates more efficiently, safely, and profitably for years to come.

Frequently Asked Questions

Q1: How do control and automation systems benefit from acoustic treatment?

Acoustic treatment reduces noise interference, enabling clearer communication and more accurate monitoring in environments with control and automation systems. Operators can hear alarms distinctly, make better decisions, and experience less fatigue, ultimately improving overall system performance and safety.

Q2: What acoustic rating should control room doors achieve?

Control room doors housing sensitive control and automation systems should achieve a minimum STC (Sound Transmission Class) rating of 40-50. This rating effectively blocks most industrial noise while allowing normal door operation. Higher ratings up to STC 60 are recommended for extremely noisy environments.

Q3: Can acoustic solutions be retrofitted around existing automation equipment?

Yes, most acoustic solutions can be implemented around existing control and automation systems. Modular acoustic enclosures, portable barriers, and wall-mounted panels offer flexibility for retrofit applications. However, planning during facility design stages typically yields more comprehensive and cost-effective results.

Q4: How much noise reduction can acoustic enclosures achieve?

Professional acoustic enclosures for automated equipment typically reduce noise levels by 20-35 decibels. The exact reduction depends on enclosure design, material selection, and the specific noise frequencies generated by your automation systems equipment. Custom solutions may achieve even greater reductions for specific applications.

Q5: What maintenance do industrial acoustic treatments require?

Industrial acoustic treatments require minimal maintenance but regular inspection. Check door seals quarterly, clean acoustic panels semi-annually to prevent dust accumulation, and inspect mounting hardware annually. Replace damaged components promptly to maintain acoustic performance around your automation systems.